-

English (US)

Choose your country or region:

Europe

Asia - Australasia

Middle East - Africa

Each wastewater treatment plant is unique, with its own capacity, layout, processes, equipment and effluent limits. Every wastewater plant is also faced with rising energy and chemical costs and regulations that are becoming more stringent over time.

We embrace the challenge to continuously improve wastewater monitoring equipment and processes including:

Nitrification/denitrification

Other plant operations and optimization

Whether in primary, secondary or tertiary wastewater treatment or the promise of a Water Intelligence System such as Claros™, Hach® innovations and applications can help you stay in compliance and reduce operating costs, doing more with less.

Get the confidence that your plant is running smoothly with Hach.

See if our DR6000 is pre-programmed for the methods you utilize.

We spent years innovating the best-in-class ammonia analyser (you know as Amtax) to function with the ease you want and the accuracy you need. Introducing the lower maintenance NH6000sc with a lightweight, integrated FX6 filtration system option.

The DR3900 is designed to deliver accurate results quickly with Hach's innovative TNTplus® and LCK reagents for fast preparation and easy execution.

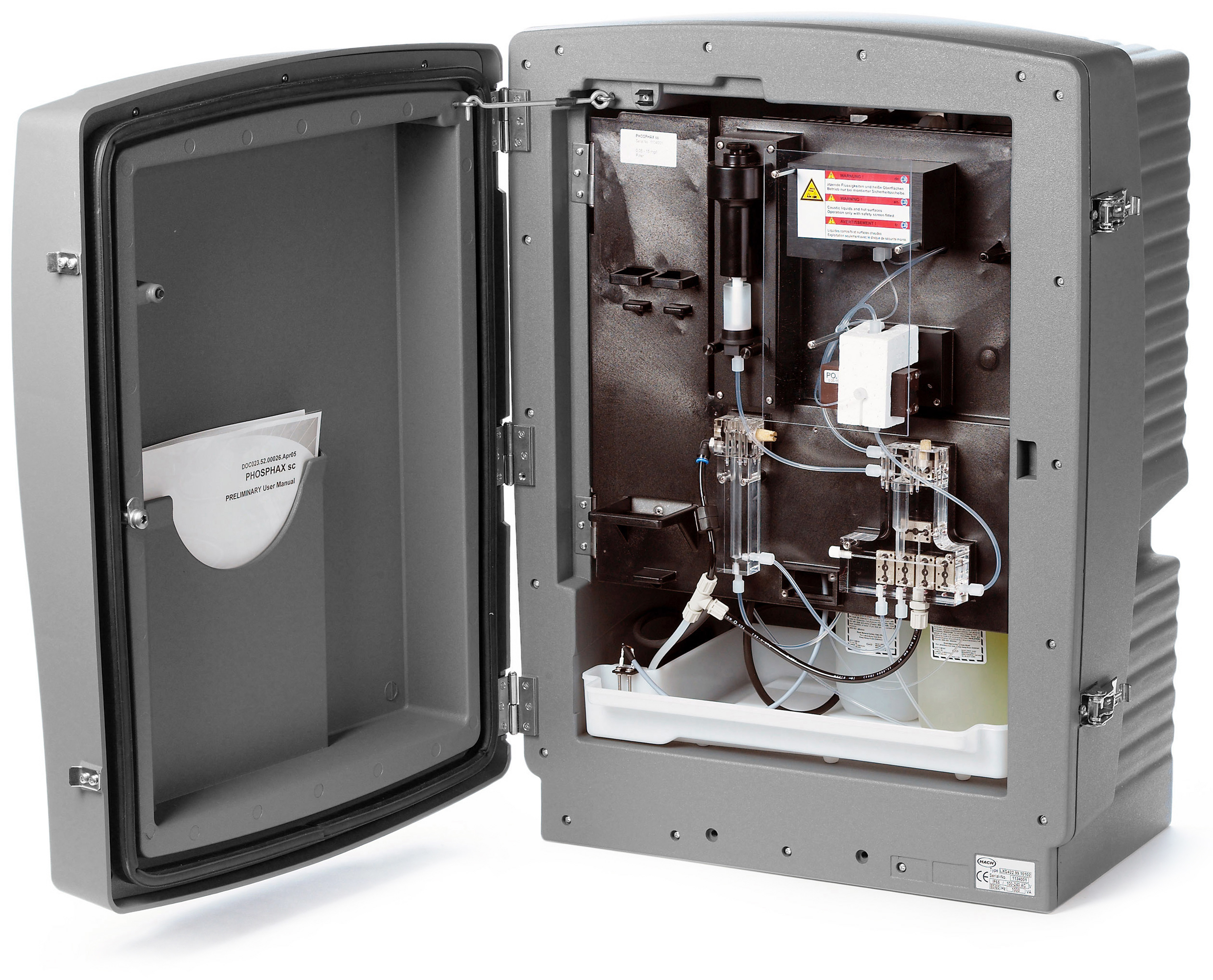

The Phosphax sc Phosphate Analyzers provides a wide measurement range for a variety of wastewater and drinking water applications.

The Solitax ts-line sc immersion probes provide accurate, color-independent suspended solids and turbidity measurements. Explore our range of highly accurate and durable TSS sensors.

Available with automatic cleaning, the TU5300sc Low Range Laser Turbidimeter dramatically reduces the time needed to get a turbidity measurement you can rely on.

Modern sanitary sewer collections systems move wastewater through a series of pipes from residential buildings, businesses and industrial sites to wastewater treatment facilities for processing and discharge. Some older systems know as combined sewer systems also carry stormwater runoff in addition to the wastewater from residential and commercial sources.

The wastewater flows through underground sewer mains, most often by gravity but sometimes assisted by pumps situated at lift stations. Depending on the topography of an area, these force mains vary in length up to a few miles long. Interceptors are locations where two lines meet and flow into a larger pipe and can include large chambers accessible by manholes.

Preliminary treatment is typically the first process within the treatment plant and consists of screening and de-gritting. Screening is the process of removing trash, rags and other debris by passing the water through a mechanical screen or rotating drum. Grit is removed by reducing the velocity of the wastewater, so that heavier inorganic particles like pebbles and sand can settle to the bottom and be removed via gravity. The grit and screenings are washed and compacted before being collected in a dumpster. These preliminary processes are very important for modern water resource recovery facilities, as grit and debris can irreparably harm downstream processes including primary clarifier mechanisms, aeration diffusers and membranes.

Interested in learning more about preliminary and primary treatment?

Secondary treatment removes the soluble organic matter, nutrients such as nitrogen and phosphorus and most of the suspended solids that escape primary treatment.

There are several opportunities and challenges for secondary treatment including:

Click here to learn about Hach solutions for nutrient removal.

Interested in learning more about secondary treatment?

In tertiary treatment, techniques such as filtration, disinfection, carbon absorption and other processes are used to remove the remaining organic load, suspended or dissolved solids, pathogens and heavy metals that pass through other treatment processes. Also called effluent polishing, tertiary treatment raises the effluent quality to the level suitable to its intended use, whether for discharge into lakes, rivers, oceans, reuse as non-crop irrigation (parks, golf courses, greenways, etc.), groundwater recharge or in certain cases, as influent to drinking water plants. Wastewater plant effluent must be monitored to ensure compliance with effluent permit limits, which vary based on jurisdiction and country.

Interested in learning more about tertiary treatment?

The method for handling the sludge removed from the process depends on the volume of solids as well as other site-specific conditions. Aerobic digestion is often used by facilities less than eight million gallons per day of inflow. Waste Activated Sludge and if present, Primary Sludge, are added to an aerated reactor where microorganisms feast on the organics and microorganisms present in the sludge to reduce the volatile solids content and the overall mass of sludge.

Interested in learning more about sludge management?

While effluent from wastewater treatment facilities is commonly discharged to the environment in rivers, oceans, or other bodies of water, there are a variety of other options for discharge. These include agricultural irrigation; use in parks and recreational facilities (golf courses and sports field irrigation, snow making); wildlife habitat or aquifer/wetland/marsh recharging; industrial uses such as process water; street cleaning; or direct potable reuse where water is sent to a drinking water plant for further treatment.

Interested in learning more about effluent & reuse?

A growing field of expertise within the wastewater treatment industry, Water Intelligence Systems use digital technologies, advanced sensors, controllers, and algorithms to allow plant operators to increase efficiencies leading to overall cost savings in running the plant.

ClarosTM, the Water Intelligence System from Hach, integrates all plant data sources, including system data, device data, and manually-collected data, driving decisions to maximize efficiency and cost savings.

With these systems, data on flow rate, water composition, dissolved-oxygen, nutrient levels, and other factors are more easily tracked and verified. This leads to more responsive treatment options, automation capabilities, and data visualization and report generation.

Using data-driven insights into water quality, flow rate, and other factors, operators can reduce overtreatment (chemicals as well as aeration blower run time) while knowing their plant will remain within compliance limits.

As regulations become more stringent and plants need to find cost-savings, Water Intelligence Systems such as Claros will become more important and widely adopted. And with the Hach’s growing suite of Claros-Enabled sensors, controllers, devices, Process Management systems, and lab equipment, operators can configure a system that fits the unique requirements of any plant.

Interested in learning more?

Regulations and permit limits vary from region to region and country to country. Generally, target limits are established by the acting authority, and plants measure and report to demonstrate compliance with established limits. In this way, important parameters that indicate water quality and environmental and health standards are monitored and maintained, ensuring the continued health and safety of the populations being served.

For information regarding regulations in the US: https://www.epa.gov/npdes

For information regarding regulations in the EU: https://www.eea.europa.eu/themes/water/water-management

Contact us for tech support, service, sales, or to get a quote.